If you’re considering purchasing a 3D printer, there are a number of features to look for. We’ll run down a number of must-have features for your 3D printer.

The intended use of your 3D printer is going to be the best starting point to decide which features are most important. For the purpose of this article, we’ll focus mainly on FFF/FDM type 3D printers (those that extrude plastic filament). The build size of the printer is obviously a major component, and the size of the parts you’re looking to print will likely dictate the size you should look for. Keep in mind that larger parts take substantially longer to build, and for low-end machines, a smaller print area may prove to be more reliable, as it’s easier to maintain good tolerances over a smaller frame and build area. Take in to consideration the size of parts you need to print. For cosplay helmets, a 12-inch cube may be ideal. I’ve found that I rarely print anything bigger than a 6″ cube size, so in my opinion, you’re better off buying the highest quality printer with an acceptable build size, than the largest printer available in your budget.

Moving beyond size, here is a breakdown of other features to consider.

Temperature

Hot End

The extruded plastic filament passes through what is called a “hot end”. There are various types of hot ends and nozzles. If you want to print with higher temperature filaments like nylon and polycarbonate at 260C+, then you’ll want to be sure that your 3D printer has an all-metal hot end. Many 3D printers can be upgraded to hot-ends like the E3D V6, so if your printer does not come stock with an all-metal hot-end, check to see if its compatible with an all metal replacement.

Heated Build Plate

A heated build plate is pretty standard. Generally speaking, a heated bed is not required (but helpful) for printing PLA material. If you’re looking to print just about anything else, you’ll need a heated bed. If you’re printing material like polycarbonate, make sure your heated bed can reach temps of 110C. If you are printing a lot with these high bed temps, you may want to also look for a machine that has a 24v power supply, as a 12v can take a long time to heat to 110C. We’re talking about several minutes, so it’s not a big inconvenience if 12v is your only choice.

Removable Build Plate

Some 3D printers now offer a removable build plate. This is very helpful for removing printed parts, which at times can be difficult to remove, especially from inside the printer. Removable plates allow you more room to work on removing the parts, and eliminates potential damage to the printer. Another added feature to many removable plates is they are made with flexible material that can bend and easily release the part with little effort.

Enclosure

If you’re printing ABS, you’ll want an enclosure to help regulate the temperature of the build chamber. This will help keep the material from contracting and curling as it cools. An enclosure also help to keep drafts from affecting your prints, and will keep in fumes generated while printing. ABS material specifically produces some unhealty fumes, so an enclosure offers both the temperature and somewhat of a safety advantage. If you’re able to attach a duct and vent the enclosure to the outdoors, even better.

Sensors

Automatic Bed Leveling

Some printers are equipped with sensors that enable the automatic bed leveling.

If you’re not familiar with 3D printing, having a level print bed is absolutely required for a good print. If the bed is out of level, the first layer may not stick. On some machines, the bed leveling is done manually, usually with adjustment screws that are used to lower or raise a corner of the bed. Levelling the bed will usually take from a few minutes, to a half hour depending on how much testing you do to verify that the bed is level. Auto-leveling basically eliminates the need to periodically level the bed, and makes a first layer adhesion a bit more fool-proof.

Filament Out Sensor

Some printers are equipped with sensors to detect that the plastic filament has run out or is jammed. This can be very helpful if you run out or get a jam during a very long print. There is nothing worse than being 23 hours into a 24 hour print, and having the job stop because of a jam. Printers equipped with sensors like this will pause the print an allow you to resume.

Before you consider this a must-have, keep in mind that you can usually determine the amount of material left on a spool by weight, and slicing software will tell you how much material is needed for the print, so it’s easy enough to prevent the printer from running out during a job.

Also, if a job pauses for a length of time, the adhesion of new layer printing on top of the layer that has been cooled for some time, may not hold as well (most likely will not). So you may be left with a visible line where the part was paused, and the part will be weaker at that layer. Depending on how much surface contact there is between the two halves, the two may split apart easily. So the filament sensor, I see as a decent upgrade if its available, but by no means is a requirement.

Mesh Bed Leveling

It’s nearly impossible for a print bed to be perfectly flat. The leveling process ensures that the bed is level, but typically only measures a few points on the bed (corners). Mesh bed leveling measures multiple points across the bed and compensates for any high and low points. This ensures a good first layer and bed adhesion. The larger the build bed, the more likely this is going to be a helpful feature..

Filament Extruder: Direct-Drive vs. Bowden

Direct Drive

On a direct drive system, the extruder motor is mounted on the print head assembly and pulls the filament into the print head. This is a very reliable method for feeding filament as there is little gap between the motor and the nozzle. The down-side to this setup is that the extruder motor adds weight to the print head assembly. This added weight can slow down the speed at which the printhead can move, and can also reduce accuracy in movement.

Bowden

On a Bowden system, the extruder motor is mounted to the frame of the printer and fed to the print head assembly using a bowden tube, usually teflon tubing. This type of system reduces the weight of the print head allowing for faster and more accurate printing. Also likely creates less wear and tear on the motors and belts that drive the print head. The bowden system pushes the filament from the extruder motor, through the tube, and to the head.

The down-side to this type of system is that pushing the filament through a tube means it will be difficult to print with flexible materials. Also, there is some risk of bowden tubes wearing and causing fricting and under-extrusion in prints, especially if you print with any abrasive filled materials.

Overall the direct-drive system seems like the most reliable and problem-free, though it comes with some reduction in performance (speed). Once print speed is reduced, you should be able to get the same accuracy of print on either system.

Nozzles

The nozzle is where the molten plastic is deposited on to the build plate. The type of metal and size of the bore in the nozzle can have a big impact on how the machine prints.

The most common nozzle is a .4mm brass nozzle. This will work just fine for printing most standard filaments. Some filaments, such as carbon fiber filled or glow-in-the-dark materials are abrasive and will ruin a standard brass nozzle quickly. If you’re planning to use these materials, you’ll want to make sure that the printer you choose has an easily replaceable nozzle, and also that it uses a standard sized nozzle and not something proprietary. IF you buy an inexpensive printer that requires that only works with their brand of nozzles, you may end up paying more in the long-run, or being limited on what you can do with the printer.

Nozzle Size

The .4mm bore works just fine for most prints. It provides a nice blend of detail and print speed.

The larger the bore hole in the nozzle, the more plastic that is deposited, and thus the faster you can print. For example, if you are printing an object with two perimeter walls and using a .4mm nozzle, you can achieve the same wall thickness in one pass of a .8mm nozzle. So you can print walls, roofs and floors, twice as fast. The down-side of using a larger bore is that you lose the ability to print smaller details. Since every line and dot of plastic is .8mm size, there is not way to produce details smaller than .8mm. This means you will end up with a more dull look when printing things like faces or text. If you need to print objects with thinner walls or with greater details, a smaller bore nozzle would be a good choice. Nozzles can get down to .2mm or .15mm in size. Keep in mind that doing from .4 to .2 will basically double the amount of time it takes to print a part, and the smaller the bore, the more likely the nozzle will jam. Any filled materials print best with .4 or higher. Smaller bore nozzles will allow you to print smaller objects with detail.

Nozzle Material

Nozzles are commonly made from brass. If you’re printing with abrasive materials, you’ll want to use a plated nozzle or hardened steel. The Olsen Ruby nozzle is also an option if you have the budget. What you’re looking for is wear-resistance and good thermal conductivity. Hardened steel conduct heat as well as brass, so you’ll need to adjust your print temperature if you switch from brass to hardened steel. In my experience, the difference is only a few degrees.

If you’re planning to print anything that will contact food, a stainless steel nozzle may also be a good choice. Though, you sacrifice some heat conductivity for a more food safe metal.

Ease of Replacement

If you’re planning to switch between nozzle sizes, or just do a lot of printing. Make sure the nozzle is easily replaceable. For many printers the nozzle simply un-screwed from the printhead with a wrench or socket. Take a look at instructions for replacing the nozzle before you buy a printer, just to ensure its something you’ll be willing to do regularly.

Build Size

If you don’t have a specific intent for your 3D printer, you could probably start with a smaller system that prints even a 6” cube, and you’ll find that a lot of what you want to print fits inside that build area. You can also cut a model in to multiple pieces and glue them together after their print, allowing you to produce parts larger than your printer’s build area. This works, but can be a tedious project, so if you’re planning to print large sized parts (like a cosplay helmet), you may want to opt for a printer with a larger build area, like a 10” cube.

Small printers can be had for well under $200, and can work quite well. The larger size will start closer to $500. Do keep in mind that the larger the build platform the more precise the printer has to be made to maintain proper level and tolerances to produce a good prints. A smaller printer can be leveled more easily, and will be more forgiving if is not level. With a larger printer any minor skews in the frame or motion system will be even magnified as it moves across a much larger area. In other words, a $130 4x4” 3D printer may produce much more accurate prints than a $500 10x10” 3D printer. Though the $500 printer does seem like more bang for your buck, if you’re planning to make engineering parts on a larger printer, you may want to spend a little more for a nicer system with tighter tolerances.

Summary

This list is by no means a complete list of features of 3D printers, there are different 3D print technologies, and even within FDM models, many different component types and motion systems to choose from. The features we’ve reviewed are the basic features that most first-time users should be concerned with. Not all printers will include all features, so be sure to consider what you intend to print, and be sure your printer has the features required to do what you want to do. Most common are going to be the heated bed, and an easily changeable nozzle. Not having those are pretty much a deal-breaker.

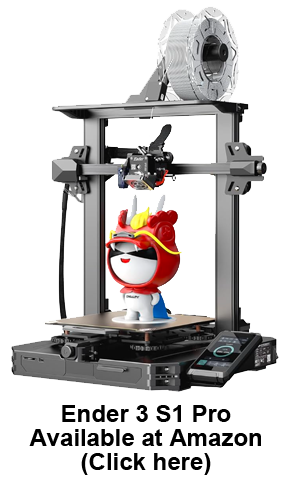

If you’re looking for an affordable printer to start your journey into 3D printing, you may want to consider the Creality Ender 3. It includes many of the essential features, as well as some nice extras like resume after power failure. For the price it seems to be a great value, and would be my recommendation if you’re looking to start with a more affordable option.

As an Amazon Associate, I earn from qualifying purchases.